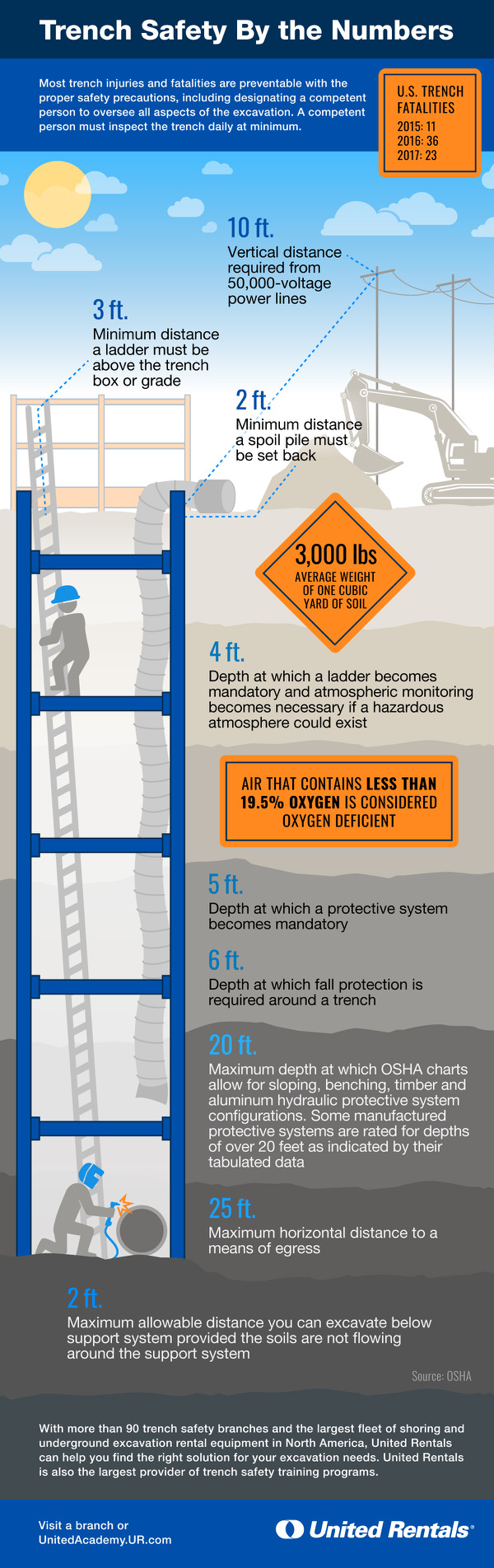

Here are some of the important numbers the competent person must keep in mind relating to everything from surface encumbrances to access and egress to hazardous atmospheres.

Trench work can be complicated. It’s also potentially dangerous, as evidenced by troubling fatality rates. In April 2019, the industry saw more trench fatalities than in any previous month on record. That’s why using a trench protective system when required is so important, as is following the rules for the safe and appropriate use of these systems.

RELATED: Download the eBook: United Rentals Guide to Trench Safety

The charts in Appendices B, C and D of OSHA’s 1926 Subpart P must be followed when using sloping, benching, timber and aluminum hydraulic protective system configurations up to a depth of 20 feet. Any deviation from the charts, including excavations deeper than 20 feet, requires written approval from a registered professional engineer (RPE).

When using a manufacturer’s protective system, it’s essential to consult the tabulated data (tables and charts) the manufacturer provides for using the equipment and to stay within the limitations the data outlines. You may need to consult an RPE if the design parameters of the system will be exceeded.

It’s critical that the competent person, who is responsible for determining the best protective system and inspecting the trench, the protective system and the adjacent areas at least daily, is adequately experienced and trained.

Here are some of the important numbers the competent person must keep in mind relating to everything from surface encumbrances to access and egress to hazardous atmospheres.